Social Good: A Goal Beyond Green

Whether it’s a pen used once and passed along, a t-shirt worn for 25 years or a photo of a trip to Disney in a logoed frame, hung in your parent’s living room, like any other tangible possession, there’s a chance that promotional products may, one day, be discarded. No brand wants its promo items contributing to the 121 million tons of waste that end up in the nation’s landfills each year, so the environmental impact of promotional products is top of mind for many industry businesses. But Woodridge, Illinois-based supplier Orbus Exhibit and Display Group has made protecting and preserving the environment one of its core values.

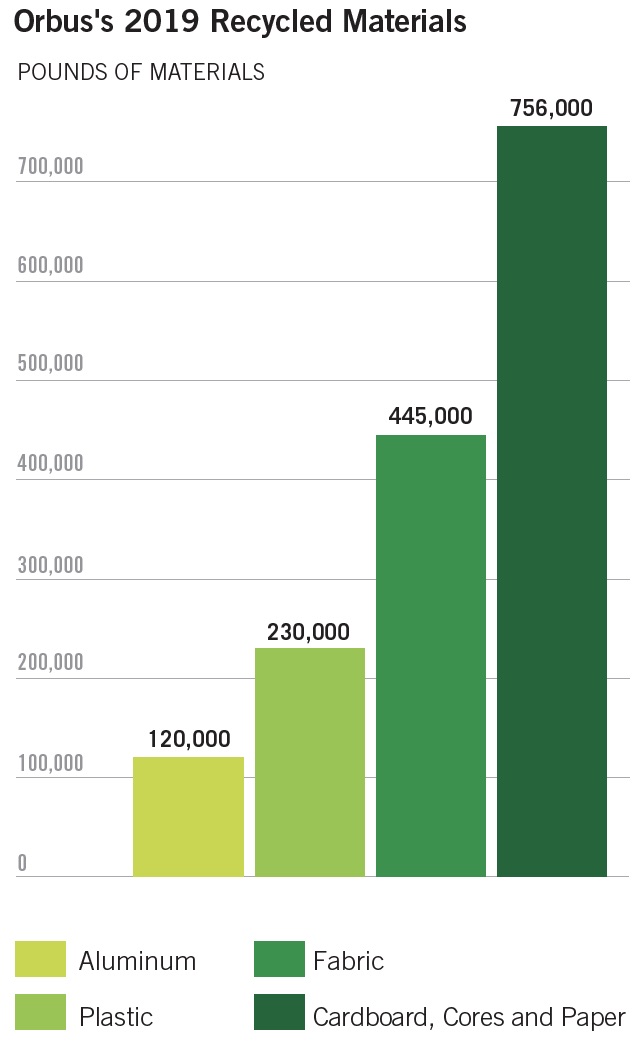

Orbus, a wholesale supplier and manufacturer of display, exhibit, graphic and event solutions founded in 2001, diverted 87 percent of its total waste from landfills in 2019. “Orbus prints over 26,000 square feet of display graphics alone each day—[and] that coupled with other aspects of operations, we produce a lot of recyclable items,” says Jim Concannon, operations manager. Since 2017, Orbus has recycled more than 1,444 tons of cardboard, cores and paper, 944 tons of fabric, 468 tons of plastic and 253 tons of aluminum.

“It’s a continuous effort,” says Natalie Whited, vice president of marketing at Orbus. “As one of the largest exhibit and display manufacturers in the U.S., we obviously have a lot of raw materials and goods that we have to find recycling partners to take. And that, sometimes, is the challenge—finding the right local sources. Not all operations can take the quantity of materials that we need to provide. We are constantly trying to find different sources [that] can recycle and reuse to repurpose into something that can be consumed.”

In order to continuously surpass environmental goals, Orbus has devoted talent and resources to its environmental management program. Orbus has two full-time team members, one in Nevada and another in Illinois, who are dedicated to the recycling efforts, and several others who manage two full dock bays that are dedicated exclusively to sorting and distributing recyclable materials.

In order to continuously surpass environmental goals, Orbus has devoted talent and resources to its environmental management program. Orbus has two full-time team members, one in Nevada and another in Illinois, who are dedicated to the recycling efforts, and several others who manage two full dock bays that are dedicated exclusively to sorting and distributing recyclable materials.

“We have several team members in place whose full-time role is dedicated to achieving efficiency and gains, whether it be in our environmental management practices, our ISO standards, which we adhere to, or just generally making improvements to what we are able to recycle in our operations,” Whited says.

Whited adds that an environmental management program is critical to successfully diverting Orbus’s recyclables from landfills. “No program is ever perfect,” she says. “It’s never outlined to recycle 100 percent, but it’s a matter of chipping away at that in every way possible.”

Not only is Orbus reducing waste in landfills, but the company is also reducing its carbon footprint. Partnering with environmentally-conscious vendors like UPS, which plants trees across the U.S. as part of its carbon-neutral shipping program, helps Orbus achieve this. “We have to ship our goods,” Whited says. “But, if we know that the shipping partner we work with also plants trees across national forests in the U.S. to mitigate their contribution to the environment, that’s definitely something we are in support of and finding vendors like that is a continuous effort.”

In the future, Whited says eco-friendly efforts at Orbus will go beyond mass-recycling. “We ask ourselves, ‘What else can we do?’ Some things we are looking into are, for the two buildings that we operate in, putting on a green roof and even installing electric car chargers in the parking lot.”

Following Orbus’s diversion of 87 percent of its waste from landfills in 2019, Whited says the goal for 2020 is to exceed the bar set in 2018, when the supplier diverted 90 percent of its waste.

“It’s not a matter of competing [with another company],” says Whited. “It’s a matter of taking those core values as very critical and important for our business and our leadership. We want to see other companies emulate what we are doing, so we, as a collective, can all divert waste materials from landfills. Hopefully, we’ll set the stage for other companies to follow suit and eventually, work with one another.”

–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––

Kristina Valdez is associate editor of PPB.