Summit Attendees Tour CPSC Lab To Observe Testing Practices, Protocols

Product Responsibility Summit attendees were treated to a tour of the Consumer Product Safety Commission’s (CPSC) National Product Testing and Evaluation Center in Rockville, Maryland on Monday. Opened in 2011 and located near the Summit’s Bethesda location, the testing center houses the CPSC’s state-of-the-art testing labs and equipment, and engineering staff.

“I had been to the first CPSC lab and this center is just phenomenal,” says Leeton Lee, vice president of regulatory compliance and general counsel at supplier ETS Express, Inc. in Oxnard, California. “The new technology and the testing equipment is impressive. It’s obvious that the federal government has given them the money they need to do their job, because before they were working with bubble gum and duct tape. That’s a little bit of an exaggeration there, but it was pretty rudimentary. Nowadays, it’s obvious they have the top-of-the-line equipment, apparatus and special tools they needed to truly follow the testing protocols. And they have very skilled and highly qualified people here. You could see during the presentation and the tour. I was very impressed.”

Andrew Stadnik, associate executive director of the CPSC’s Directorate for Laboratory Sciences, welcomed tour participants and spoke on the testing center’s mission and challenges. Products come to the center for testing when issues are reported or concerns are noted by CPSC inspectors in the field.

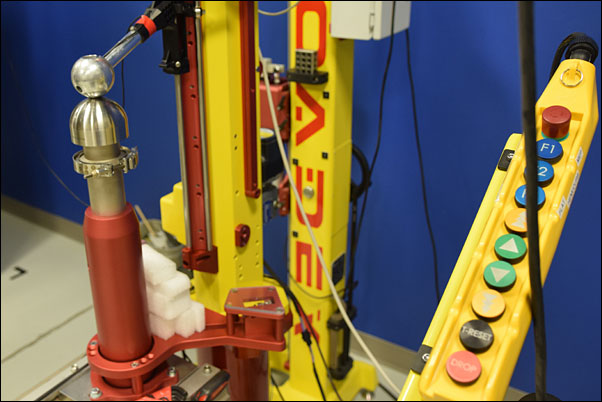

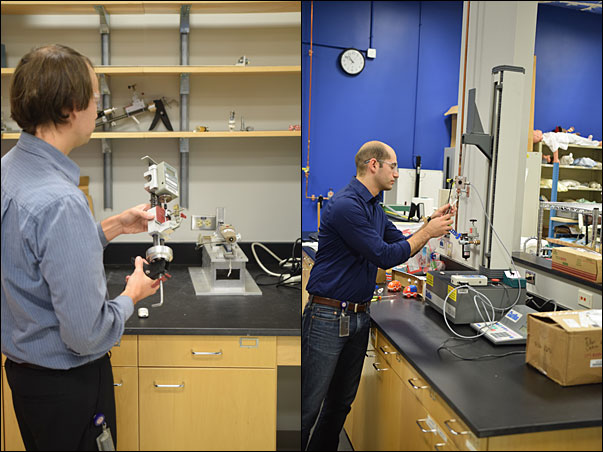

Following introductions, tour attendees were divided into small groups led by testing center staff. The tours took participants through the center’s myriad labs, including the children’s product testing lab, the chemical product testing lab and the flammability testing lab.

“It was a really good experience for me and I’m glad I came,” says Troy Jones, vice president of operations at Stellar Imports in Hawthorne, California. “On a daily basis, we work with a lot of high-profile accounts and it’s important to maintain testing protocols to ensure compliance, and to be able to come into a facility like this and see firsthand how those protocols are being tested has been very informative. It helps me get a visual of how the tests are run and the types of machinery and equipment used. And to speak to the different engineers and lab techs, and get insight on what they’re looking for and what they’re looking at is huge.”